|

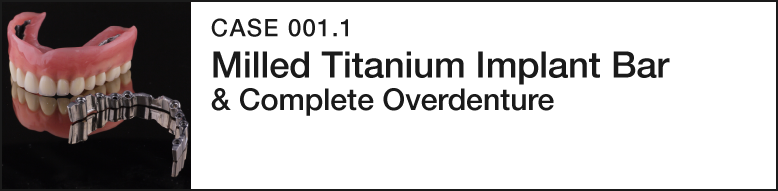

001 Milled Titanium Implant Bar 002 Screw-retained Zirconia Br 003 Screw-retained Zirconia Br 004 Hybrid Acrylic with Ti Frame 005 Milled PMMA Eggshell Temp 006 Screw-retained Zirconia Br

|

| home > interesting cases > milled titanium implant bar > case 001.1 | |

|

|

STEP1 TEETH-SETUP AND TRY-IN |

|

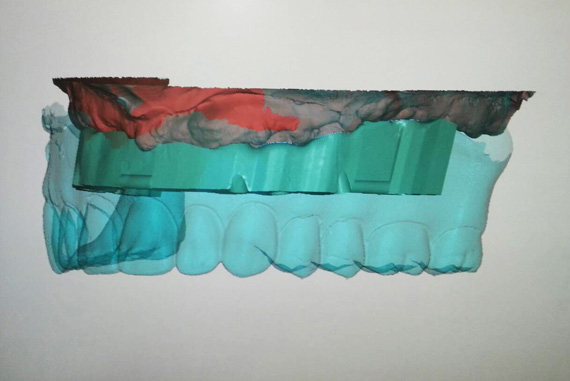

STEP1 TEETH-SETUP AND TRY-IN Relined baseplate in order to seat well on implant and working model. |

|

|

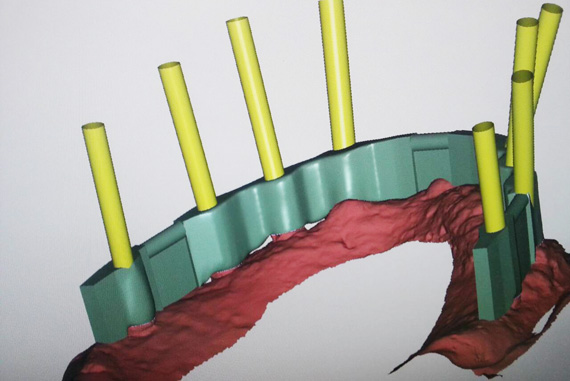

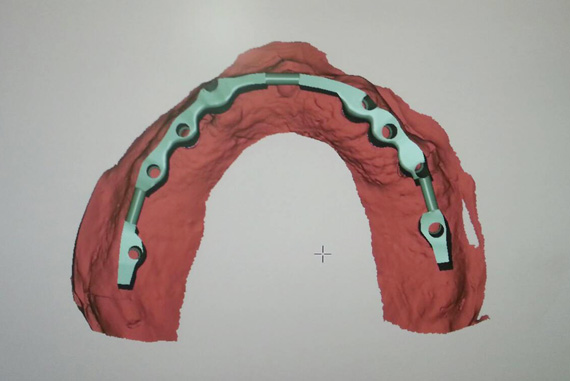

STEP2 CAD-CAM Try-in denture was scanned into CAD software and used as situation model. Bar could be designed precisely and provide sufficient space for the substructure of overdenture. |

|

STEP2 CAD-CAM |

|

STEP2 CAD-CAM |

|

STEP2 CAD-CAM |

STEP3 MILLED TITANIUM BAR |

|

STEP3 MILLED TITANIUM BAR |

|

STEP3 MILLED TITANIUM BAR |

|

STEP4 THE FRAME OF OVERDENTURE TThe substructure made of Co-Cr casting with conventional lost-wax technique. |

|

STEP4 THE FRAME OF OVERDENTURE TThe substructure made of Co-Cr casting with conventional lost-wax technique. |

|

STEP5 FINAL PROSTHESIS

|

|

STEP5 FINAL PROSTHESIS |

|

STEP5 FINAL PROSTHESIS |

|

STEP5 FINAL PROSTHESIS |

|

STEP5 FINAL PROSTHESIS |

|